Polyamide Blends with Low Weight and High Rigidity

For numerous application developments, the subject of weight reduction is gaining in importance. For example, in combination with a special processing method – and thanks to its low density – a new blend (polyamide + polypropylene) can achieve weight savings up to 30 %.

In its search for weight-saving potentials, the plastics industry is continuously finding new solutions. Through addition of chemically coupled polypropylene, and after moisture absorption, a newly developed polyamide blend (PA + PP) from AKRO-PLASTIC GmbH in Niederzissen, Germany, exhibits the same strength as a standard polyamide. Depending on application and the degree of reinforcement, the blends already save 7...10 % of density compared with standard polyamides, and have a better flowability (Table 1). In order to reduce component weight even further, one approach is to charge the melt with a chemical or physical foaming agent.

Further Weight Saving through Foaming

Foam injection molding is one possibility for further weight reduction. For that, a propellant is injected into the melt under pressure, which foams the plastic after or during mold filling. With these so-called physical foams, the gas is injected directly into the melt under high pressure in a sophisticated process. The resolution of patent issues has helped to increase popularity of this process. Typically weight reductions of 6...7 % can be achieved. With chemical foaming, a chemical foaming agent is added to the plastic by means of a masterbatch. During processing, and under the melting conditions, the propellant is formed in the plasticizing unit. Here, it dissolves in the melt and foams the plastic during processing after pressure relieve. Apart from flexibility, the advantage of this masterbatch solution lies in the option of including other components in the masterbatch formulation. This has further positive effects on foam formation, and depending on the polymer used, the processing method can be optimized even further. Previously, the selection of chemical foaming agents for engineering plastics was limited to a great extent to exothermal foaming agents. However, these energy-releasing systems lead to longer cooling times. The toxicologic classification of exothermal foaming agents is problematic. Due to their predictable negative effects on mechanical properties, the development of marketable endothermic foaming agents (energy-absorbing systems) stagnated practically at the level of the late 1990s. Previously, a component thickness of less than 3 mm was considered inadequate for injection molding of structural foam. The success of physical foaming processes such as MuCell (supplier: Trexel, Inc., Wilmington, MA/USA) and Cellmould (supplier: Wittmann Battenfeld GmbH & Co. KG, Meinerzhagen, Germany) is partially due to the lack of a suitable foaming agent masterbatch system. Microcellular foam structures are created primarily by the high gas load in the plastic and the enormous pressure difference used in this processing method. Complex processing technology, reduced surface quality and lacking processing flexibility with smaller lots are seen as collateral effects.

Masterbatches without Negative Effects

New masterbatch formulations are helping to reduce these adverse effects. The evaluation of fundamental [1] and current research results provided a basis for the development of new masterbatch systems. These eliminate the damaging influence of the foaming agent in the formulation and simultaneously promote the microcellular foams. The nucleating rate Nhet is largely responsible for determining size and quantity of the foam cells. By means of Colton’s findings [1], it can be derived [2] as:

Whereby: C1 = concentration of nucleating seeds, f1 = probability of contact, ΔG*het= free energy of nucleation, Δp = pressure drop, γ = surface tension of the melt.

This relationship permits the necessary parameters and influencing possibilities for producing a fine-celled foam structure to be derived. These possibilities are not limited to achieving a maximum pressure drop, as is the case with purely physical foaming processes. Modern foaming agent masterbatches combine the advantages of dust-free and safe handling with the provision of nucleating seeds and additives, which permit an optimally tuned application to be realized with the process. Figure 1 clearly shows the influence of a maximized nucleating rate. During the development of technical compounds for lightweight construction, the focus was not placed on obtaining absolute weight reduction, but rather on finding a combination of maximum weight saving with the best-possible preservation of mechanical properties exhibited by technical plastics, such as,

- maintaining rigidity,

- good strength,

- good surface, and

- microcellular foam structure.

With mutually matched systems, the balance between surface quality, mechanical properties (rigidity and bending strength), and weight reduction is controlled primarily by the process. The underlying tests were carried out with a mold for tensile test bar, whose long flow path and very high aspect ratio provide highly unfavorable conditions for good surface quality and uniform microcellular foam distribution.

However, as a final result it was possible to produce moldings that combine a presentable surface with significant weight saving, and simultaneously provide excellent mechanical characteristics. Regarding process control, two different methods were used for the production of 4 mm shouldered test bars made of a (PA + PP) blend reinforced with 20 % carbon fibers, plus 3.5 % masterbatch AF-Complex® PE 990310 TM from AF-Color. The results are compared in Table 2, whereby the respective compound, charged with foaming agent and produced by means of the standard process, serves as zero value. Through the addition of masterbatch, the proportion of carbon fibers in the final compound is reduced according to the dosing.

Component Production

Full shot: The mold is filled completely, compacted, and the shut-off nozzle is closed without a hold pressure phase (energy saving), so that the machine can already start the next metering stroke. This method achieves a weight reduction of 4 % compared with the standard process without foaming agent. The mechanical values remain practically identical. The advantage of this method is that the components can be produced practically warpage-free, because the hold pressure is maintained by the compound itself, and is therefore equally effective everywhere.

Moreover, the foaming agent improves flowability, but reduces the weight only moderately. The density reduction is concentrated on the hottest point. As a result, and depending on the component, the cooling capacity required for the component’s core is decreased, leading to a 10% shorter cooling time. Regarding component surface quality, the results of this method are just as good as those obtained with the standard process.

Short shot: The mold is filled almost completely, but without compacting the melt. Also this method does not use hold pressure, and achieves a weight reduction of 13 % compared with the zero value. The modulus of elasticity is reduced by 15 %, i. e. roughly the same amount as the weight reduction. However, the flexural modulus remains above the zero value.

The reason for this is explained by the second moment of area: The external surface area is included in rigidity with x³. This has an effect on the lower shrinkage of the system charged with foaming agent. On the other hand, there is 13 % less of matrix material, which results in a corresponding reduction of rigidity.

Summary

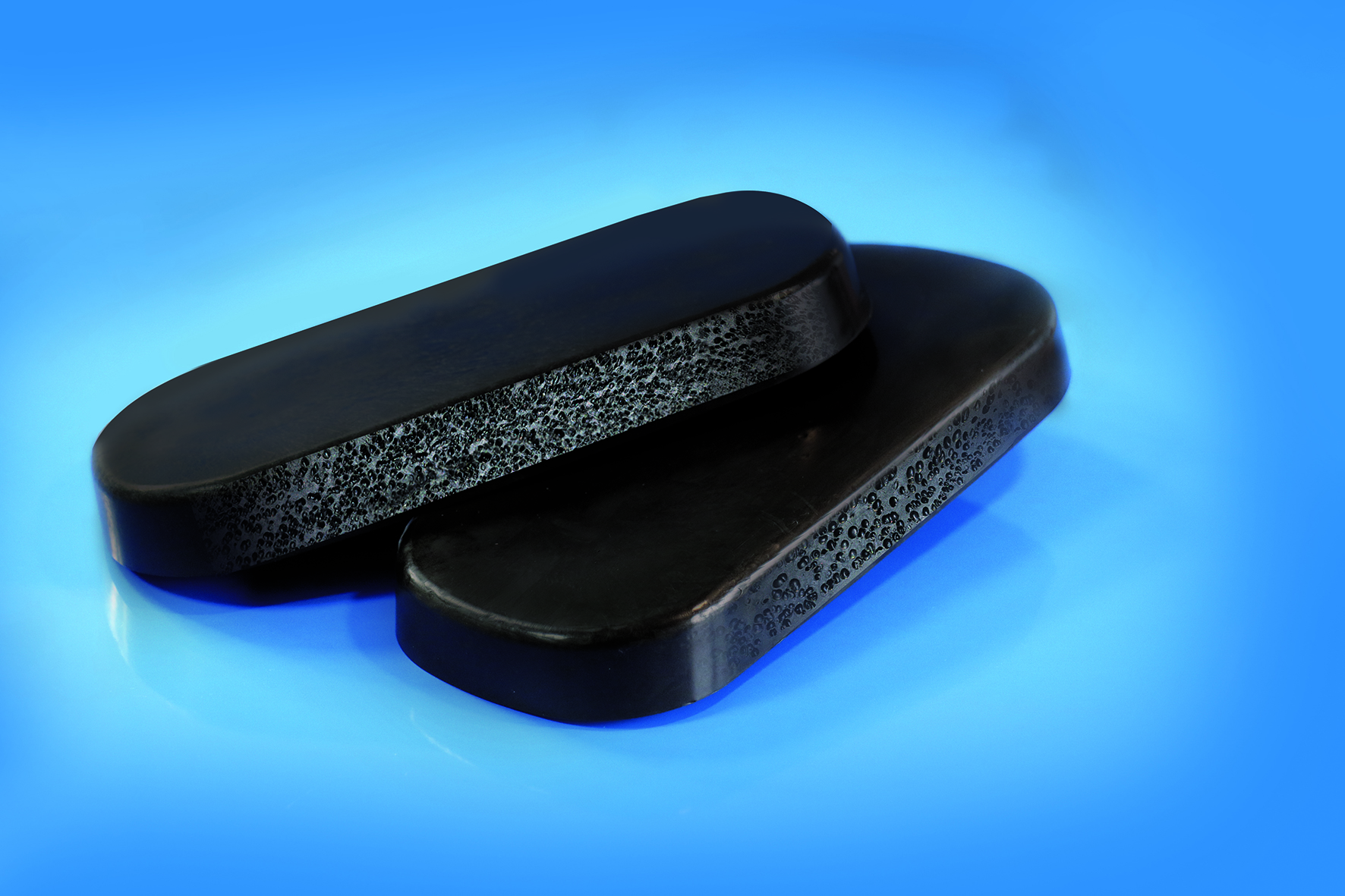

New foaming agents lead to weight reductions of engineering plastics without a significant impairment of their properties. The use of mutually matched systems, e.g. the (PA+PP) AKROMID® Lite blend and the foaming agent masterbatch AF-Complex® PE 990310 TM, is recommendable. In the case described here, the density of AKROMID® B3 ICF 20 1 Lite black (5296) was reduced by 13 % through the addition of a foaming agent. A further weight reduction of 8 % was achieved by means of blend technology (PA + PP). Compared with polyamide 6 GF 30, an overall weight reduction of 30 % was possible thanks to the innovative ICF carbon fiber from AKRO-PLASTIC – in addition to higher tensile strength and bending resistance. Hereby, the density of this foamed compound is significantly lower than that of water (Title figure), and has a flexural modulus of more than 12,000 MPa (Figure 2).

References:

1 Colton, J.S.: The nucleation of microcellular thermoplastic foam. Dissertation (MIT Thesis), 1985

2 Altstädt, V.; Mantey, A.: Thermoplast Schaumspritzgießen. Carl Hanser Verlag, Munich, Germany 2011

The Authors

Thilo Stier works as head of Sales & Innovation with AKRO-PLASTIC GmbH in Niederzissen, Germany

Dr. Inno Gaul works as head of Research & Development with AF-COLOR, a branch of AKRO-PLASTIC GmbH in Niederzissen

English

English Chinese

Chinese